Welcome to ukmicrolights.com

Back to navigation page (click here)

MAYDAY MAYDAY MAYDAY!

The throttle gets stuck!

Welcome to ukmicrolights.com

Wind 260 15 knots, Vis >10K, Cloud base >10,000ft

Eddsfield East Yorkshire: Runway in use 27, Grass, 800m TORA, 775 LDA due to trees prior to the 27 Threshold.

Pilot Kevin Taylor 256 Group A + 105 flexwing microlights Hours total.

On Type 80 hours on type in last 6 months. 20 hours in last 90 days. 10 hours in last 30 days.

G-OURO Europa trigear NSI Subaru.

The initial flight of the day was a take off at 14.50 on 26th January 2003. The Europa G-OURO took off from Eddsfield for a local trip, which was expected to be around 45 mins.

The flight was uneventful and landed at approach 15.40. After backtracking I decided to complete one further circuit.

After levelling at 1000ft on the crosswind leg I found that I wasn't able to close the throttle below 4200 RPM. I coarsened up the prop and tried to close the throttle but it appeared jammed. I also found that opening the throttle any further caused rough running. I elected to use the available power to climb in to the overhead in order to investigate the problem and think about the problem!. I tried some simulated descent approaches but with such high revs there was no way I could reduce the speed below 130kts unless in a climb. It became apparent that closing the throttle was not an option and decided the landing would have to be a glide approach with the engine shut down.

At this point I considered my options and put out a Mayday call on 121.5. I also decided that I had limited time before night and must make an immediate decision on a diversion. Given the obstructions and very wet runway surface at my home base I elected Humberside Airport knowing that the available runways were long and would give the best chance of an engine off glide approach.

I immediately set 190 for Humberside while passing my details to D&D, the nature of my problem and my intention to divert to Humberside. I was asked to squawk 7700, my position was identified and I was given a steer of 180 direct for Humberside.

I noticed I had a ground speed of 128 knots and I quickly did a rough calculation on fuel to make sure I could get there OK. However I was alarmed at the 28 Ltrs per hour fuel burn. My main concern though was the amount of daylight time left and knowing that by the time I arrived it would be dusk!

It quickly became apparent the engine wasn't running smoothly at all and the application of carb heat didn't help. I also tried different prop setting but again this was no help to the problem. I was beginning to wonder if the engine was going to keep running and my track gave me two further options. Beverley Linley Hill airfield a grass strip with 700 meters grass and RAF Leconfield the base of the RAF Seaking S.A.R. Helicopter. I asked D&D to check out both these options for me with emphasis on Leconfield, as I was now almost overhead. Coincidentally at this point S128 the Seaking came on frequency and advised me they had been tasked to launch and shadow me. I asked S128 if Leconfield was available and they advised me the runways were not useable.

I continued my track to Humberside and S128 was quickly shadowing me, however at this point I was extremely concerned about the roughness of the engine. Approaching Hull and the Humbler Bridge I decided that although it would take me away from my direct track I must stay well to the West of Hull in order that I had more clear ground for a Engine out landing should the engine fail which was looking quite likely at this point! At the same time I pulled my speed back in order to climb from 1500ft to 2000ft in order to buy more time in the event of an engine failure and allow me more options knowing that I would have to cross the river Humber which is 1.5 to 2 miles at the point I was to cross. I was also aware that Brough was 3 miles west of my location, which was looking more like the only option given that the engine was so poor! My ground speed was good and with 10 miles to Humberside I took the decision to bite the bullet and hope the engine would continue to run. I also knew that S128 was with me and should the engine fail and I had to land out, there would be a helicopter crew on scene immediately.

I soon arrived over head Humberside and for some time I'd had clearance to land on any runway with any inbound traffic diverted or holding. The wind was 260 15 knots gusting 20 knots which made 27 the best option and although it was the shortest of the two runways at 1054 Meters it was into wind. I joined overhead Humberside at 2000 ft and instructed them that a downwind approach on 27 left was my intention. On base leg and tight in to 27 I advised ATC that I was turning the engine off and this would be a dead stick glide approach to a full stop. I would not be able to restart and I would need recovery in order to vacate the runway. S128 was cleared to follow me in to the ATZ.

In the glide I knew I was too high and that was my plan of action. I got my speed back and took full flap immediately knowing I had loads of height. I made my base leg longer than I needed to deliberately overshooting the final turn, follow by a turn back in order to burn off height and set up final on to 27. At this point I knew I WOULD make the runway but an overwhelming urge came over me to tell ATC “I don't like this”. It was all so quite I needed to talk and to know they were at least listening was of some help. This was not to say at anytime I felt I wouldn't make the runway, as I knew I would but switching the engine of was a last resort but I had no option. All the practice in training (and since) helped but nothing could prepare anyone for the real thing.

The glide on finals was fine however I continued a few S turns to burn off height and at the same time told ATC “I know I am drifting away from the runway but I'm just burning off height and they shouldn't worry. I concentrated at all times on my approach speed but it felt very natural by feel and angle of attack with references to my ASI confirming I had the speed nailed. I landed about halfway down the runway at which point I was joined by 3 big red fire engines and S128 flew past for a close look to check I was OK, before they departed for home. I shut down the electrics and was joined by a fire crew who asked if I was OK and aid well done for getting it down. The ordeal was over and the plane and myself were fine. We towed the plane off the runway to the parking area where I left it for the night.

To follow are two further parts to this incident.

One to highlight what caused the problem

and what I felt I could have done better.

On return to the plane the following day (Sunday) I was sure the problem must be obvious and expected to see a major and obvious problem. Maybe something jamming against the throttle control but that wouldn't explain the reason for the rough running.

The cowls were removed but there were no visual restrictions on the throttle assembly arm. Then I noticed something different. There was a hole where a screw should be on the carb air box? I removed the rest of the screws and removed the air box cover.

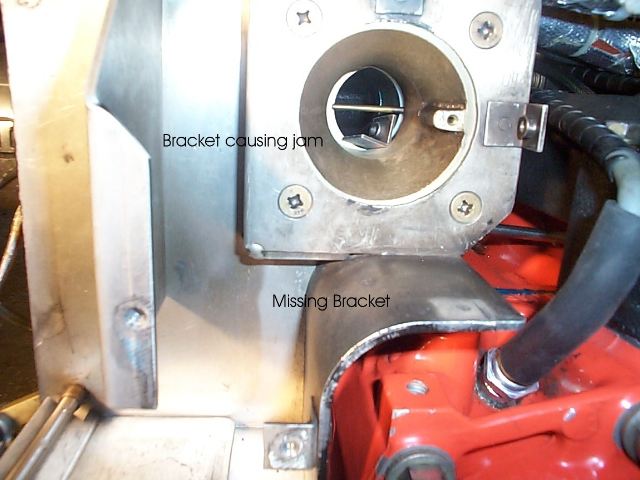

There inside the throttle bore opening was a metal bracket. It had been sucked up in to the mouth of the bore and was stopping the throttle plate from closing!

See the photo picture of carb with filter

and plastic cover removed

At this point I realized how precariously this was positioned and how if it had moved just slightly it would have gone past the metering needle and un doubtedly in to the engine! How lucky I was.

I removed it and was able to fly home that

day!

Could it have been avoided??: Probably!

During routine maintenance I had seen the

bracket was attached to the plastic cowl

(not shown in the picture) and not welded

to the casting like the others. I didn't

think anything of it and assumed it was there

as a stop to guide correct lining up of the

cowl, as it had been like this since I purchased

the plane. In hindsight I NOW realize it

should have been attached to the casting

and obviously if it had then it couldn't

have become loose. Also I'm sure a drop of

threadlock would have stopped the screw vibrating

loose out of the plastic cover so it would

have held the bracket to the cover

Isn't hindsight a wonderful thing!

So what would I have done differently?.

Looking back I am kicking myself for not

noticing the fitting of this bracket was

incorrect. Looking back NOW its obvious from

the marks on the body that the bracket was

at one time fitted by this stud/weld/rivet

what ever it is, but I missed it.

End

This site is a member of The Microlight Webring.

[ First Site | Previous | Next | Last Site | Random Site | List Sites ]